LIQUID | LIQUID

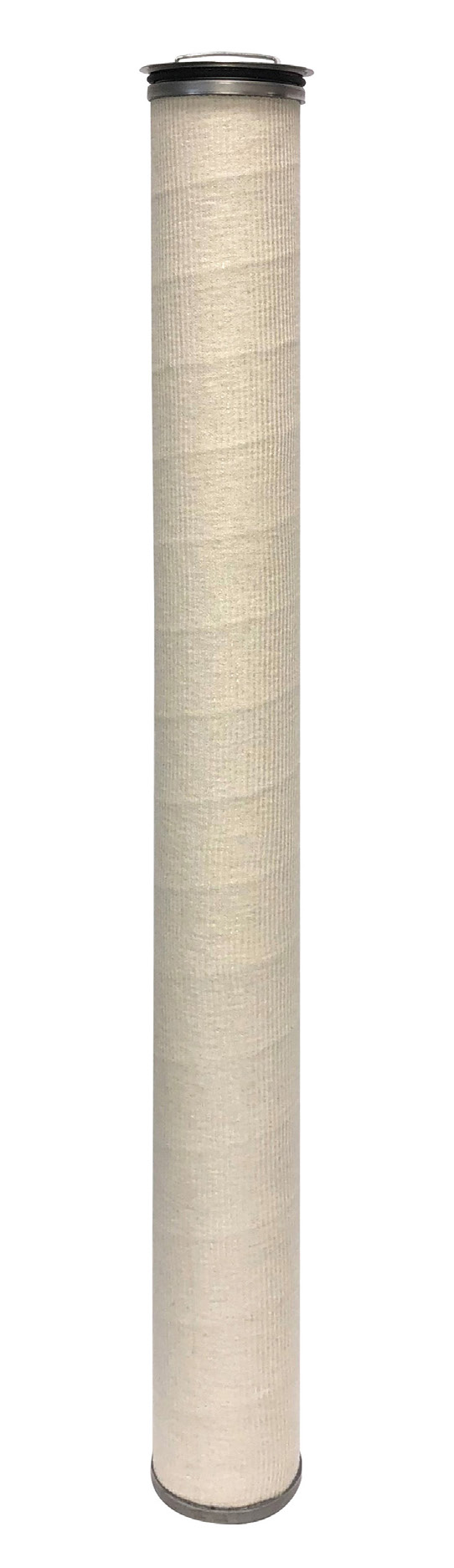

Strata | 37 Series

Cost Effective Separation

Process complications caused by emulsions can include equipment fouling, off-spec product, increased operating costs, and unscheduled shutdowns which can lead to loss of production and revenue. Emulsions are mixtures of two or more liquids in which there is a fine dispersion of one liquid into another known as the continuous or bulk phase. Properly designed coalescing systems separate the dispersed liquid from the continuous phase of the process stream so that downstream contamination is avoided.

Our Strata Liquid-Liquid Separation technology offers a complete line of coalescing elements to address even the most complex emulsions. Strata coalescing systems provide excellent coalescing efficiency, capacity, and liquid contaminant removal to eliminate costly problems and provide process reliability.

Benefits

- High efficiency liquid-liquid coalescence technology provides reliable discontinuous liquid contaminant removal of up to 5% by volume

- Capable of reducing discontinuous liquid phase concentration down to 15 ppmv or less

- Designed to maximize system flow rates and discontinuous liquid phase removal capacity in a minimal footprint

- Engineered to minimize pressure drop and maximize service life

- Offered with a wide range of materials of construction to provide the most cost effective solution for each application

- Operator friendly designs allows for easy installation and extraction of the coalescers

Common Applications

- Water removal from refined products (diesel, gasoline, kerosene, LPG, etc)

- Water removal from hydrocarbon condensates

- Water removal from LPG and NGL

- Water removal from chemicals

- Oil removal/recovery from water streams

- Amine removal from hydrocarbons

- Caustic removal from fuels

- Hydrocarbon removal from quench water

CONTACT US TODAY FOR ADDITIONAL INFORMATION

Call 1.888.436.0849 or fill out the form.